DIGITALISATION and automation in the mining industry has been hastened by the Covid-19 lockdown, said Reuters citing the comment of major firms and their partners at the Imarc mining conference in Melbourne this week.

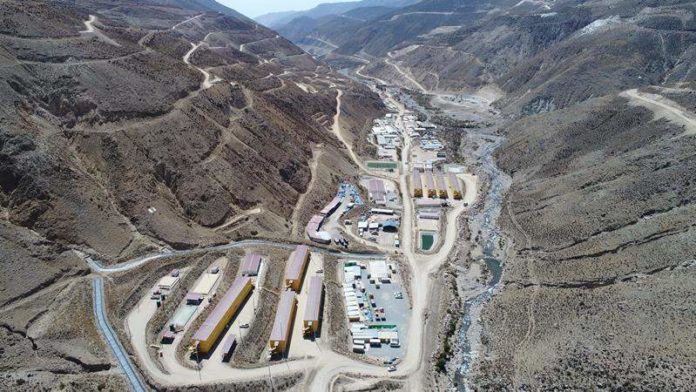

That trend will drive down costs quicker, leading to smaller, cleaner mines where more can be done with fewer people, said Reuters.

Efficiencies of this kind, combined with new technology, will help diversified miner Anglo American carve out another 10% to 20% of costs in the next three to five years, said the group’s CEO, Mark Cutifani.

“In using automation and industrial processes, we have changed mining methods,” he said. “Anglo is using bulk ore sorting and it plans to roll that through our sites in the next few years.” Improved methods of sorting ore grades at its copper mines are helping Anglo cut its energy intensity, he added.

“The pandemic has forced us to think about how we can do more of the work that had to happen on site, remotely… (and) how we do those tasks with less people,” said Suresh Vadnagra, chief technology officer at Newcrest Mining, one of the world’s largest gold-mining firms.

Australia’s Big Three iron ore miners already have “digital twins”, or big city control centres to let them manage parts of their operations from hundreds of kilometres away, but such sites are becoming more common, said Reuters.

Blasting the ground to collect ore offers an example of how big data is being used to make operations more efficient.

Manually drilled blast holes can have small differences in relation to their location on a plan, as well as to each other, which can sometimes mean a blast sequence is not efficient.

Now a detonator put in the bottom of a blast hole can function as a sensor that can provide information such as moisture content and signal its position relative to the rest.