GLENCORE is to build the UK’s first battery recycling facility processing a proposed 10,000 tons a year of lithium-ion batteries.

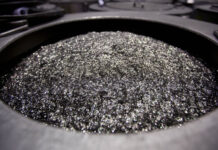

The investment, which will be in joint venture with Britishvolt, a battery technology investment an research firm, follows a joint venture announced by Glencore in January with US firm Managem to produce cobalt as well as specialised nickel and lithium products from battery scrap materials or ‘black mass’.

Both joint ventures represent a push by Glencore in to the business of the circular economy which it believes will ease supply of critical metals to the electric mobility industry. It will also further Glencore’s target of becoming a net zero total carbon emitter by 2050.

“This recycling partnership complements our long-term supply agreement for responsible cobalt from our operations in Norway and the Democratic Republic of Congo,” said David Brocas, head trader of cobalt at Glencore.

The UK battery recycling facility will be located at Glencore’s Britannia Refined Metals (BRM) in Northfleet, Kent. BRM will continue with its current production of trading operations, the group said. In line with its agreement, BRM will process all of Britishvolt’s battery manufacturing scrap from its Gigafactory in Blyth.

Glencore said the facility was expected to be operational by mid-2023 with a long-term goal of being 100% powered by renewable energy. Additional recycling technologies will be considered including black mass into battery grade raw materials.

Said Glencore: “The bold aim is to help support the creation of a genuinely circular economy that supplies recycled materials and minerals back into the battery supply chain”.

There are no major recycling facilities in the UK despite large amounts of lithium-ion battery packs are available for recycling, said Glencore citing research by the Faraday Institution, a research institute. Currently, used batteries are exported to European facilities for recycling, it said.

There are an estimated 12.85 million tons of electric vehicle lithium-ion batteries that will go offline between 2021 and 2030, according to Greenpeace. “End of life EV batteries will become a valuable part of the battery supply chain and could further the creation of high-tech UK jobs,” said Glencore.